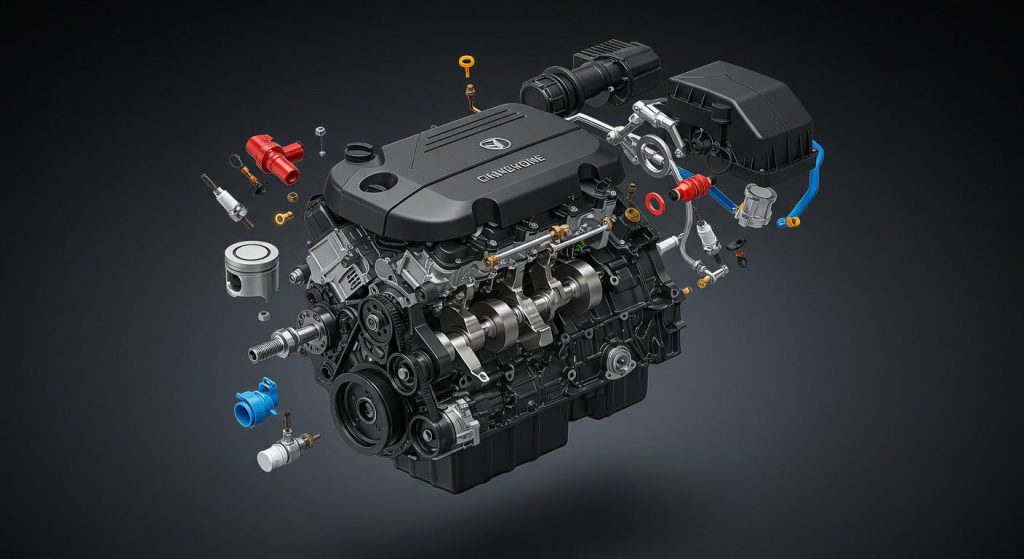

Have you ever found yourself next to your vehicle marveling at the purring engine while pondering, what really happens when I turn the key? Talking about magic, it certainly is exceptional when one turns the key, and boom your vehicle is ready to hit the streets. By the engine alone, the vehicle is composed of more than a hundred pieces that all have a single motive: providing mobility to the user.

We will be exploring each component of an engine to gain further insight and under the hood power. Termed, ‘the guide’, will open new horizons of the vehicle through understanding of its components which no other person will provide you.

Let’s dissect the engine further to see what makes it function to the level it does. Along the way, we will learn more about how the powerplant under the hood works.

1. The Rotating Assembly: The Origin of Power

The rotating assembly is fundamental to your engine’s function. The explosive force contained in the fuel is now ready to be harnessed in the form of motion. It all begins with pistons, which are attached to a crankshaft through connecting rods and crankshaft bearings. An ensemble of these parts transforms the linear movement of the pistons into rotational motion that ultimately spins your drive shaft and wheels.

In need of comfort while driving? Smooth transitions are accomplished by the flywheel, which regulates the rotational motion and prevents jerky changes on the transmission. It is even appropriate to mention the starter motor who plays the vital role of setting parts into motion prior to combustion taking charge.

2. Timing: The Symphony of Motion

Completely true – in terms of timeline. Each engine is configured as a symphony composed of movable sections that need to work in perfect harmony with each other. The opening and closing of the valves rely, in perfect synchronization, on the participation of the camshaft and crankshaft, which work hand in hand on a timing belt that enables them. The water pump that is also powered from the timing belt connects the cooling system with timing in a single blow.

To ensure these cycles are maintained crisp, clean, and from contamination or slipping, a timing cover together with a timing belt tensioner is used. Anything outside of the proper timing is not going to be useful in fires or worse situations such as engine breakdown.

3. Cooling: Fighting the Heat of Battle

Engines produce absurd quantities of heat – due to thousands of miniature explosions every minute. That’s where your cooling system steps in. The water pump moves coolant through the passages, the thermostat controls flow with temperature, and the radiator and cooling fan expel heat into the air.

And when pressure builds?

The radiator cap ejects coolant into a reservoir, maintaining equilibrium. Because an engine that is cooked is a dead engine.

4. Lubrication: Keeping the Flow Smooth

If an engine’s AC unit is the cooling system, then the lubrification is its moisturizer. The oil pump, driven by the crankshaft, shifts oil through internal galleries, lubricating every moving part, from piston to camshaft. It passes through a filter, gets fetched through an oil pickup tube, and settles into the oil pan (a.k.a. sump).

Every detail here – from the rear main seal to the oil drain plug – guarantees that your engine is smooth instead of being cooked.

5. Airflow: Breathing Life into Combustion

That is the air filter, the intake pipe, and the throttle body, which opens a butterfly valve that lets more or less air in depending on the input from the gas pedal.

In simple words, it is the breath for the engine.

Observe the manifold where the intake breather joins; for this example, engine, we split air into four runners, each feeding a cylinder. The air control valve keeps things smooth when the drivers’ foot is off the gas pedal. We would call that idling.

6. Exhaust: Letting It All Out

The exhaust manifold, along with the front pipe, catalytic converter, muffler and tailpipe are the next components in the system. After the combustion cycle, the engine heat cycles hot gases and determines what vessel they will be exiting.

So that no combustion fumes inadvertently enter the crankcase, the PCV (Positive Crankcase Ventilation) system funnels those gasses into the intake where they can be incinerated. We like to call that rebranding, but for horsepower.

7. Electrical: Powering the Sparks

Combustion can be initiated by no ordinary method. A staggering 40,000 volts are required, far from the 12V supplied by the battery, so the ignition coil and distributor take over. Distributing sparks at precise intervals through the spark plug wires is their specialty so that the air-fuel mix is ignited.

The carcass of the alternator provides fuel while idling, the belt and pulley powered alternator charge the system, and through the harmonic balancer vibrations are dampened.

8. Fueling: The Lifeblood of Performance

Everything begins with a fuel tank that has a fuel pump (with a filter) that sends gas through fuel lines to the fuel rail. The fuel pressure regulator balances the pressure while the injectors spray fuel directly into each cylinder for optimal combustion.

Missing any of these components will show “No fuel, No fun!”. These components will surely tune your engine with the utmost precision in the amount of gas needed and the best time to get it.

9. Engine Control Unit (ECU): The Brain Behind It All

The ECU appears to be the brain with incredible intellect. It uses crankshaft, throttle, coolant temp, air intake and O2 levels as countless sensors and modifies as needed ignition timing in conjunction with air/fuel ratio and many others to keep everything operating without a hassle.

All this info goes through a harness that wires giving the engine the overall look of a system. Magical explains it best if we are honest, is pure magic.

Key Takeaways:

- Rotating assembly turns fuel power into motion through pistons and crankshaft.

- Timing system keeps valves and pistons moving in harmony via cam/crank coordination.

- Cooling components prevent the engine from overheating using water pumps and radiators.

- Lubrication system keeps parts friction-free and long-lasting with oil circulation.

- Airflow management allows your engine to breathe and regulate performance.

- Exhaust system clears out waste gases and keeps emissions under control.

- Electrical system delivers spark and keeps your battery charged through alternators and coils.

- Fueling system ensures a precise fuel supply to each cylinder for maximum efficiency.

- ECU and sensors constantly monitor and adjust engine performance like a digital maestro.

Conclusion: Know Your Engine, Love Your Drive

Every time you fire up your car, you’re unleashing a carefully choreographed performance—where pistons, sensors, belts, and valves play their roles without a hitch. And now, you know them by name.

The beauty of car enthusiasm is that there’s always more to learn. You don’t need to be a mechanic to appreciate the complexity under the hood—but understanding it? That just deepens the love. So next time you hit the gas, remember: your engine is more than a machine—it’s a masterpiece.

Take a moment. Pop the hood. Get familiar. Your car isn’t just transportation—it’s a finely tuned orchestra waiting to play.